-

Critical Asset Tracking

Drive improvements in how you track valuable assets and collect data in near real time.

-

Critical Asset Sensor

Collect and analyze data to better manage IoT-connected assets.

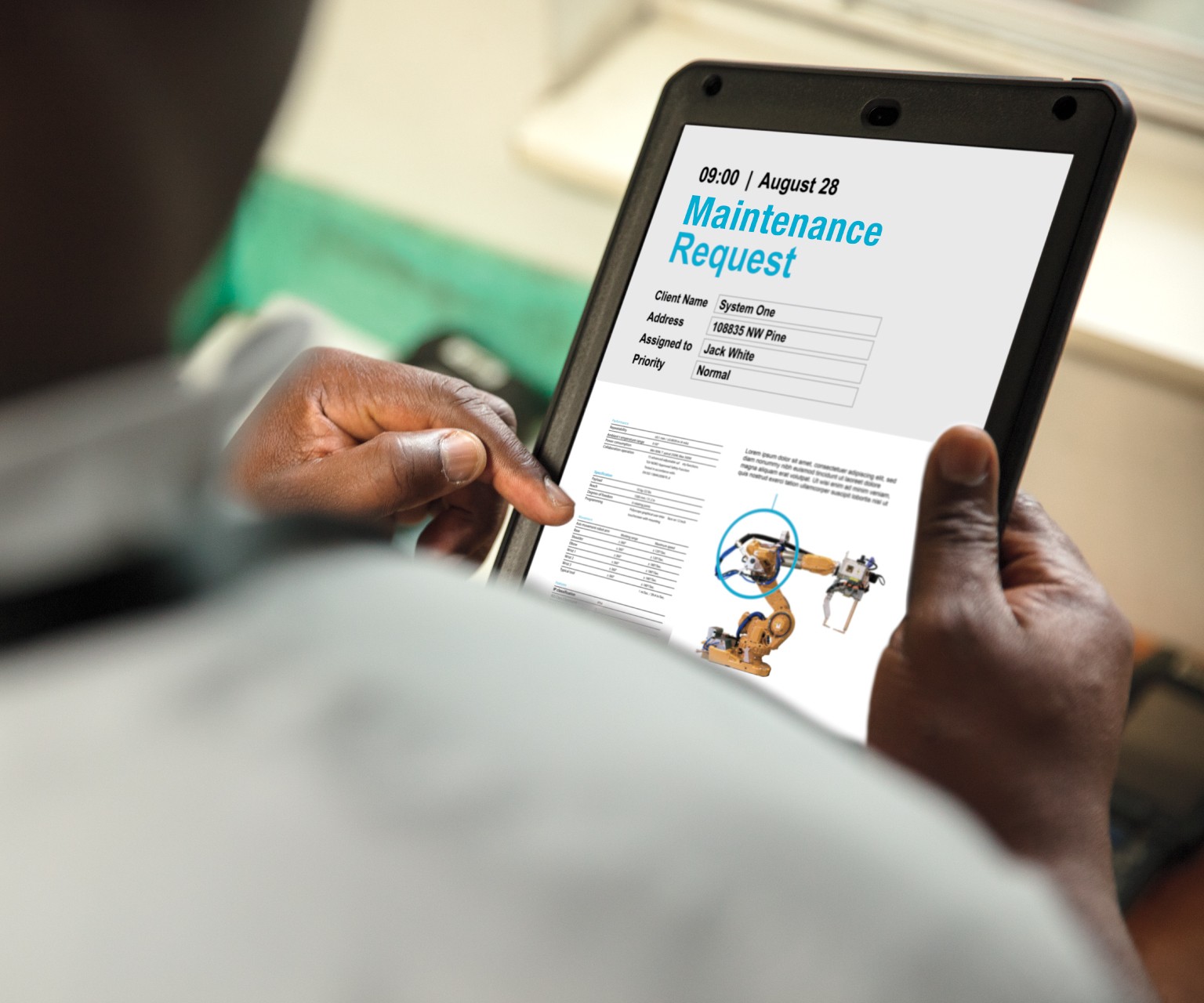

Condition Based Maintenance

Remotely monitor your equipment with an edge gateway device to help reduce the risk of downtime or failure.

Keep machinery moving with proactive maintenance.

It just got a lot easier for original equipment manufacturers (OEMs) to act proactively, rather than reactively, when it comes to equipment repairs.

Condition Based Maintenance with Edge Management and Monitoring delivers critical visibility into any equipment with an edge gateway device.

That means you can now proactively monitor any edge gateway device—including consumer products, healthcare equipment, security cameras, digital signage, robotics, manufacturing tools and more—with a reliable, secure, remote management solution.

You’ll save time and money, while extending the life of your equipment and building customer loyalty with this edge monitoring solution.

How does Condition Based Maintenance work?

Our edge device management solution transforms physical assets into virtualized, software-based models with integrated analytic fields. Third-party sensors are connected to the equipment and, using IoT Security Credentialing architecture, securely relay diagnostic data to the Condition Based Maintenance platform, so you have the insights you need to keep your equipment up and running smoothly.

Discover new ways to compete.

See how the Internet of Things (IoT) is helping transform operational data into actionable insights.

Features & benefits

With Condition Based Maintenance, you can get ahead of repairs—and the competition—by adopting a proactive maintenance model. Rather than wait until something goes wrong, you can now remotely monitor any equipment with an edge gateway device to reduce the risk of downtime or failure.

- Save money by repairing equipment, rather than replacing it

- Improve operational efficiency by reducing emergency repairs and truck rolls

- Build better customer relationships by keeping equipment running smoothly and consistently

- Create new revenue streams by enabling new services or expanding connected device offerings

Explore remote monitoring solutions.

Stay proactive about the health of your systems, spaces and assets. Get 24/7 insights from ready-to-use sensors, LTE connectivity and our cloud SaaS platform. Read the infographic and topic-specific solution briefs to learn more.

Related Products

Let's get started.

Call for Sales.

Or we'll call you.

Existing customers, sign in to your business account or explore other support options.